DuoBioX® Pro single-use bioreactor adopts bottom-stirring tank design, which can realize linear scale-up from 50L to 2,000L. Combined with 3D disposable cell culture bags independently developed and manufactured by Duoning, there bioreactors features good biocompatibility, together with flexible connection design, they can meet all requirements of complex upstream processes; their unique combination design of stirring and ventilation, not only reduce shear but also ensure excellent mass transfer and mixing performance, thus achieving good consistency during scaling-up. The DuoBioX® Pro single-use bioreactors can be widely used in various stages from process development to GMP production of biopharmaceuticals.

Product features

The cell culture bag features good biocompatibility, extremely low extractables and leachables, and ensures the safety of the product. All materials in contact with the product have passed relevant validation requirements of CFDA for single-use system and meet USP standards.

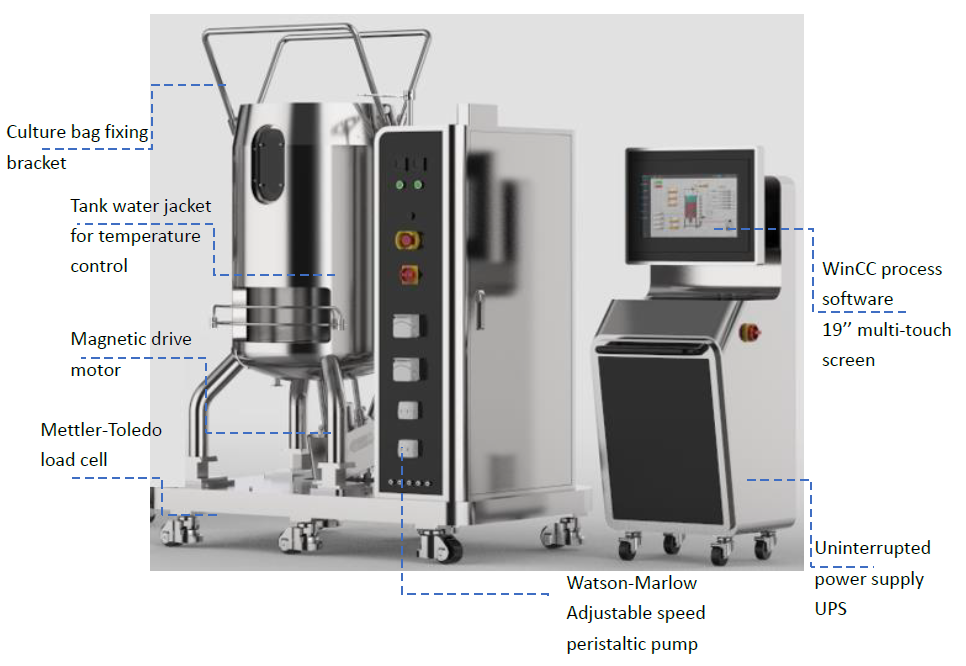

The system is designed with Siemens PLC+WinCC system, can be connected to SCADA data management system, all data can be recorded and exported, and supports audit trail, while complies with 21CFR Part 11 regulations.

The system integrates optical dissolved oxygen sensor with DO resolution of 0.1% and control accuracy of ±2%, the pH resolution is 0.01 with control accuracy of ±0.02; and temperature resolution is 0.1°C with control accuracy of ±0.5°C; the weighing accuracy is ±3‰ with pressure accuracy ±of 2%.

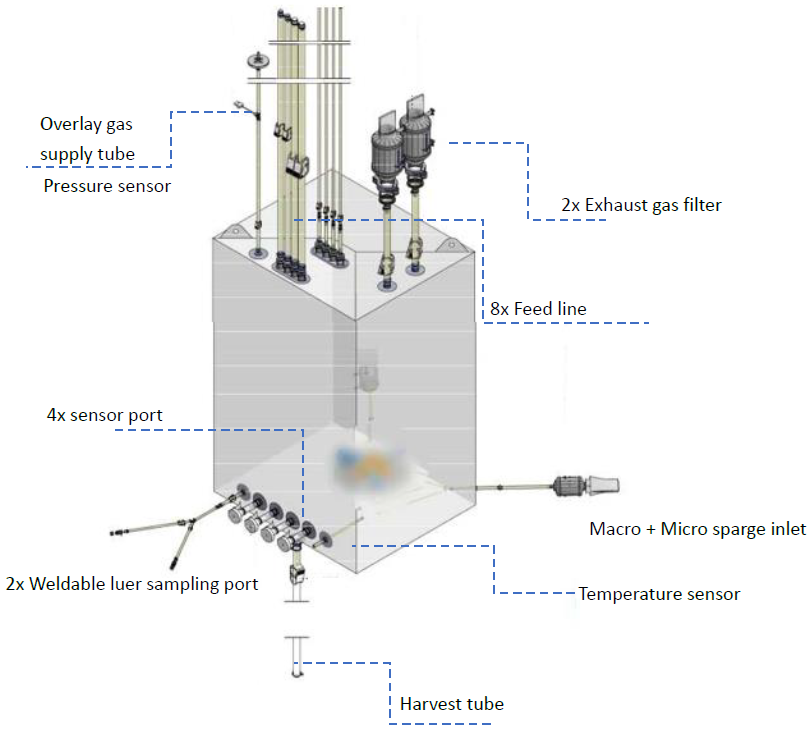

The default configuration provides 3 channels of gas supply: macro-sparge bottom gas supply (0.05 vvm oxygen, 0.05 vvm air, 0.025 vvm carbon dioxide), micro-sparge bottom gas supply (0.025 vvm oxygen), overlay gas supply (0.05 vvm oxygen, 0.05 vvm air). All use Swiss Vogtlin or German Bürkert mass flowmeter.

1-2 way exhaust heating as standard (depending on the model of the culture bag); magnetic coupling stirring device with inclined angle at the bottom, speed 0-300 rpm, temperature control range 20-50 ℃.

Mettler-Toledo high precision load cell unit.

Advantages

Hardware: The main spare parts are from industry leading suppliers, thus improve the product quality and stability of the hardware and reduce failure rate

Software: With rich experience in bioreactor development and careful consideration of characteristics of various cell culture processes, Duoning has built a mature control software system.

Service: Professional technical service team, after-sales training and services of bioreactors will be provided by experienced engineers, until end-users master all required skills.

After-sales: Relying on the strong after-sales service team of Duoning, we have set up offices in various regions, and can respond immediately to technical and after-sales problems.

Tank and I/O cabinet

Model | 50 L | 200 L | 500 L | 1,000 L | 2,000 L |

Max working volume | 50 L | 200 L | 500 L | 1,000 L | 2,000 L |

Min working volume | 13 L | 35 L | 100 L | 200 L | 350 L |

Jacket pressure resistant | Atmospheric pressure | ||||

Temperature resistant | 80℃ | ||||

Aspect ratio | 2.25:1 | 1.6:1 | 1.5:1 | ||

Jacket material | 304SS | ||||

Exhaust gas heating device | 2 | ||||

Culture bag lifting device | none | inching with protection | |||

Blade | 3 pitched blades | ||||

Blade diameter | 21.6 cm(8.5 in) | 26.6 cm(10.5 in) | 31.7 cm(12.5 in) | 41.9 cm (16.5 in) | |

Impeller position | Directly below | 15° lower side | |||

Standard gas sparger | 2 µm×1 20 µm×1 0.5 mm×2 1.0 mm×1 | 2 µm×2 20 µm×2 0.5 mm×2 1.0 mm×2 | 20 µm×6 1.0 mm×2 | 20 µm×6 1.0 mm×2 Separate macro-sparge | 20 µm×8 Separate macro-sparge |

pH sensor | 1 (2 for optional) | 2 | |||

DO Sensor | 1(2 for optional) | 2 | |||

CO2 Sensor | Optional | ||||

Gas | Air, O2, CO2, N2 | ||||

MFC | 5 as standard, can configure 6th one as optional | ||||

Built-in peristaltic pump | 2x Watson Marlow 114D 2x Watson Marlow 313D | 2x Watson Marlow 313D 2x Watson Marlow 520 | |||

External peristaltic pump | Optional maximum 1 | ||||

Temperature Control Unit (TCU) | Standard LAUDA air-cooling VC1200 Heating 2.3 kw Cooling 1.2 kw | Standard LAUDA air-cooling VC5000 Heating 4.5 kw Cooling 5.0 kw | Standard LAUDA air-cooling VC10000 Heating7.5 kw Cooling 10.0 kw | Standard LAUDA air-cooling VC10000 Heating7.5 kw Cooling 10.0 kw | |

Weighing feet | 3 | 4 | |||

Gas source | Air 200kPa, O2 200kPa, CO2 200kPa, N2 200kPa is optional. Use 1/4" or 1/2" air tube quick connection | ||||

IO cabinet power supply | Supply through control cabinet | ||||

TCU connection | TC50 | ||||

Dimension | 1,140*1650*690 mm | 1,340*760*1,910 mm | 1,420*960*2,870 mm | 1,650*1,088*2,846 mm | 1,830*1,360*3,830 mm |

Net weight | 215 kg | 260 kg | 530 kg | 940 kg | 1,377 kg |

Full load weight | 265 kg | 460 kg | 1,030 kg | 1,940 kg | 3,377 kg |

Control Cabinet

Hardware | SIEMENS IPC477E |

Dimension | 550*960*1,350 mm |

Weight | 89 kg |

Touch screen | 19 inch(52.4mm)10-point touch |

UPS | Maintain sensor and data recording for 30 minutes |

Software | SIEMENS WINCC |

Compliance | 21 CRF Part 11 |

Power | 220V, ≤2kw(w/o TCU) |

Temperature control unit (LAUDA)

Model | VC1200 | VC1200 | VC5000 | VC10000 |

Power | 220 v, 3 pins plug | 380 v, Industrial power 5 pins plug | ||

Heating power | 2.3 kw | 4.5 kw | 7.5 kw | |

Cooling power | 1.2 kw | 5.0 kw | 10.0 kw | |

Dimension | 450*550*650 mm | 550*650*970 mm | 650*670*1250 mm | |

Minimum heat dissipation interval (front, back, left, and right) | 20*20*20*20 cm | 50*50*20*20 cm | ||

Net weight | 54 kg | 57 kg | 98 kg | 147 kg |

Volume | 15 L | 15 L | 33 L | 64 L |

Temperature control range | -20℃~80℃(When the temperature is lower than 5°C, antifreeze should be used as circulating water) | |||

Circulating water pressure | 3.2 bar Max | |||

Circulating water flow rate | 37 L/min | |||

Heat dissipation | Air/water cooling | |||

Working temperature | 5 – 40 ℃ | |||

Working humidity | Max 80% @ 31 ℃ | |||

Stainless Steel Suspension Cell Culture Bioreactor

Stainless Steel Suspension Cell Culture Bioreactor

DuoBioX Explore Multi-Parallel Benchtop Glass Bioreactor

DuoBioX Explore Multi-Parallel Benchtop Glass Bioreactor

DuoWave® Rocking Single-use Bioreactor

DuoWave® Rocking Single-use Bioreactor

DuoBioX Pro Single-use Bioreactor

DuoBioX Pro Single-use Bioreactor

CHO Transient Transfection Cell Culture Medium

CHO Transient Transfection Cell Culture Medium

TransInsect Series Insect Cell Culture Medium

TransInsect Series Insect Cell Culture Medium

TransVA Series Suspension Culture Medium for Vaccine Production

TransVA Series Suspension Culture Medium for Vaccine Production

Transpro Series HEK293 Cell Culture Medium

Transpro Series HEK293 Cell Culture Medium

CHO Serum-free Cell Culture Medium

CHO Serum-free Cell Culture Medium

Relevant Documents

Copyright © Shanghai Duoning Biotechnology Co., Ltd. All Rights Reserved Sitemap | Technical Support:

Message-