DO, or dissolved oxygen, is the amount of oxygen dissolved in the bioreactor culture medium and is an important parameter for aerobic biological processes. DO affects the metabolic activity for cell growth and the yield and quality of products.

Due to the complexity and variability of the cell culture process, it is particularly important for the bioreactor to accurately monitor DO and efficiently execute the control strategy through the controller to achieve robust and stable dissolved oxygen control.

Achieving real-time monitoring and accurate regulation of DO in bioreactors is a challenging and important task. This article will introduce various factors and variables that affect oxygen transfer and consumption in bioreactors, as well as how DuoBioX® Explore bioreactors easily solve this challenge.

DuoBioX® Explore 3L Benchtop Bioreactor

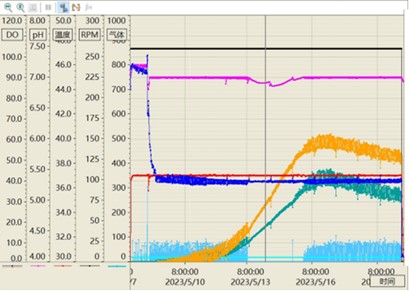

Stable Parameter Control of DuoBiox® Explore Bioreactor (CHO Cells)

Factors And Variables Affecting Dissolved Oxygen In Bioreactors

Dissolved oxygen in a bioreactor is determined by oxygen mass transfer from the gas phase to the liquid phase and the balance between liquid phase and cell consumption. Oxygen transfer rate (OTR) and oxygen uptake rate (OUR) are two key parameters for quantifying oxygen transfer and consumption in bioreactors.

OTR depends on several factors and variables, including:

Physical properties of media, such as viscosity, density, and solubility;

Geometry and dimensions of the bioreactor vessel, such as height, diameter, aspect ratio;

Stirring system of bioreactor, such as stirring paddle type, rotation speed, quantity, position;

Bioreactor sparging system, such as sparger type, flow rate, pressure, gas composition;

And the presence of baffles or other devices can enhance mixing and prevent the formation of vortices in the bioreactor.

OUR also depends on several factors and variables, including:

Types of microorganisms or cells, such as bacteria, yeast, fungi, mammalian cells;

The growth rate and biomass concentration of microorganisms or cells in a bioreactor;

Metabolic activity and product formation of microorganisms or cells in a bioreactor;

Availability and concentration of nutrients (such as sugars, nitrogen sources, vitamins, minerals) and inhibitors (such as ethanol, lactic acid) in the bioreactor.

DO Control Of DuoBioX® Explore Bioreactor:

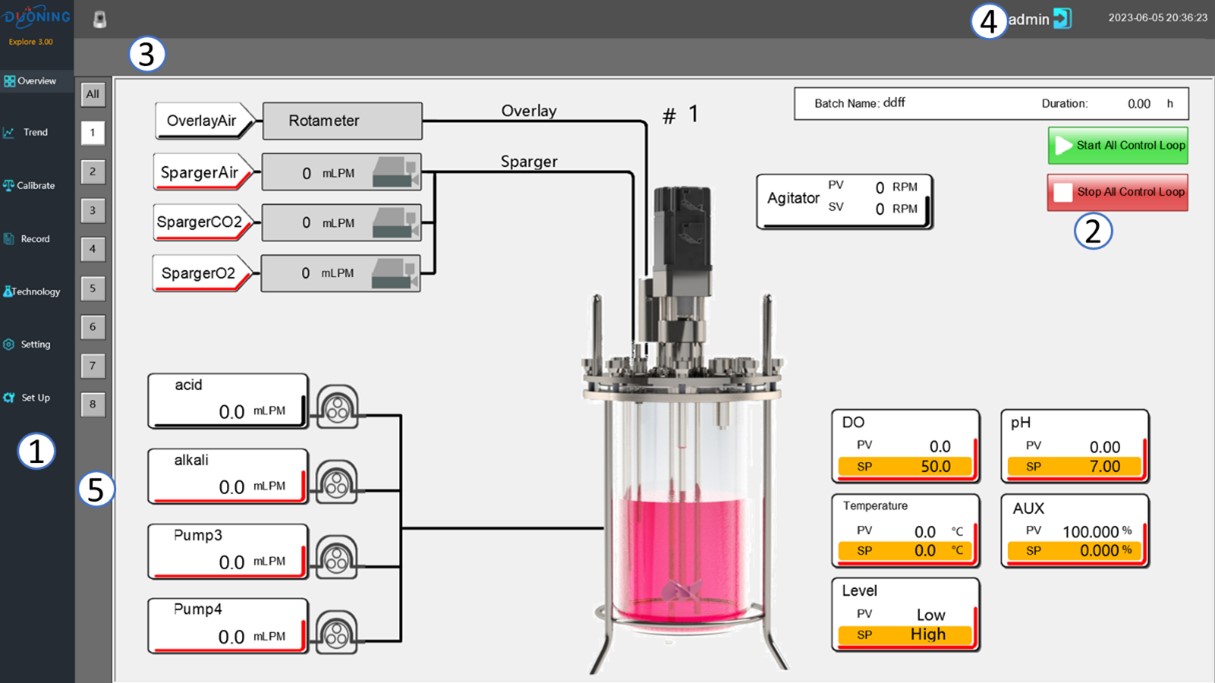

DuoBioX® Explore bioreactor is a benchtop bioreactor system with full-featured control. Similar to large-scale bioreactors, users can easily define and execute control strategies for various process parameters on Explore.

Explore Main Control Screen

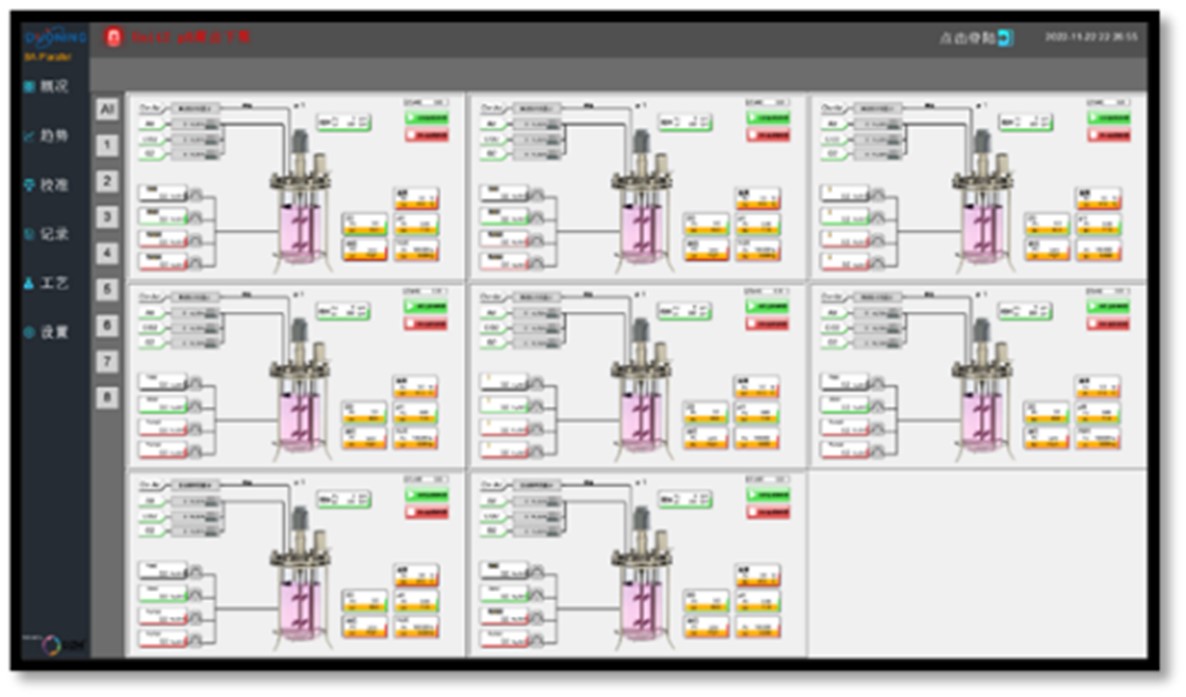

Explore SCADA Interface For Multi-Parallel Control

The DO controller consists of hardware and software used to adjust variables that affect OTR or OUR to maintain the DO concentration at the desired set point (SP). The underlying logic of DO control is "PID control", which uses a feedback loop mechanism to adjust variables that affect OTR or OUR based on the difference between the measured value and the set value. A PID controller consists of three items: Proportional (P), Integral (I), and Derivative (D). The P term adjusts the variable proportionally based on the error; the I term adjusts the variable based on the error accumulated over time; and the D term adjusts the variable based on the rate of error change.

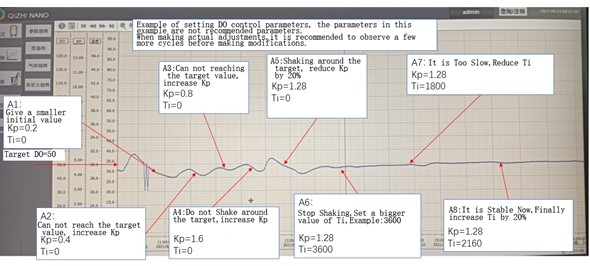

DuoBioX® Explore's PID controller parameters (P, I and D values) have adaptive mode and manual mode:

PID self-adaption: No need for users to intervene, it is simple and easy to use. Under normal operation, users can obtain excellent control effects by using self-adaption mode.

PID manual adjustment: Users can customize parameters to achieve more precise process parameter control.

P-I-D Manual Adjustment Example (DO)

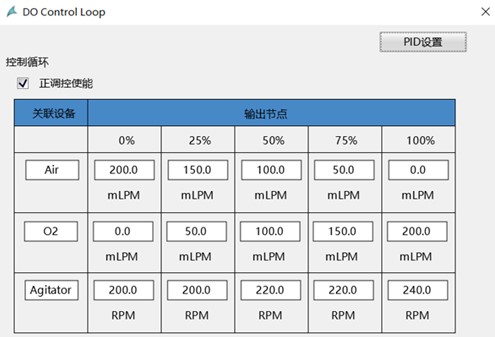

DuoBioX® Explore provides various DO control strategies to meet different user needs, including: cascade control, conditional control, and programming control.

The most commonly used DO control strategy in bioreactors is the use of DO "cascades," which involve multiple controllers that adjust different variables that affect OTR or OUR.

For example, a typical DO "cascade control" for cell culture to control OTR:

Adjust gas flow

Adjust the gas mixture composition

Adjust mixing speed

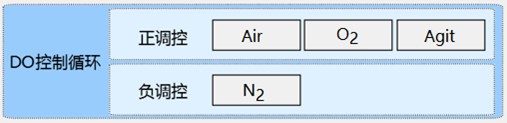

DO cascade can be set up and executed in the Explore process control software:

DuoBioX® Explore Bioreactor DO Cascade Control Strategy

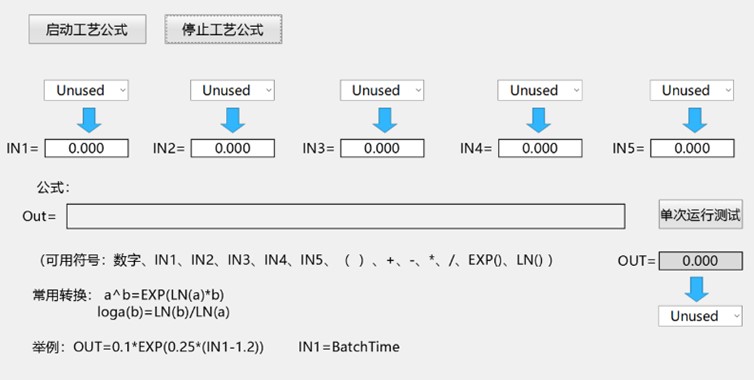

In addition, if DO control needs to be coordinated with other control parameters that affect or are affected by them, such as temperature, pH, nutrient addition, this can be achieved through the "condition control" strategy of the Explore process control software:

DuoBioX® Explore Bioreactor DO-Feed Condition Control

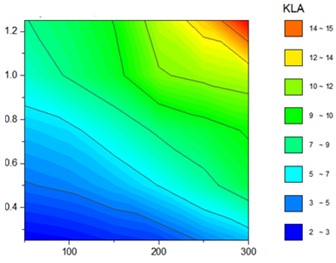

Based on the interconnection between DO, KLa, OTR, and OUR, when the tank design changes, such as changing the shape of the stirring impeller, the number of blades, the sparger pore size, the gas mass transfer effect of the bioreactor needs to be re-evaluated. At this timepoint, the "script control" function of the DuoBioX® Explore bioreactor can fully automatically complete the measurement and result output of KLa.

DuoBioX® Explore Bioreactor Script control, Kla vs. Air flow and Agitation

Conclusion

Controlling dissolved oxygen in bioreactors is a challenging and important task that requires careful monitoring and adjustment of various factors and variables that affect oxygen transport and consumption in bioreactors. There are different methods and devices used to measure and control DO in bioreactors, such as DO sensors, DO controllers, PID controllers, and DO cascades. Controlling DO in bioreactors has multiple benefits and challenges that need to be carefully considered and addressed individually to achieve optimal bioprocess performance.

DuoBioX® Explore bioreactor adopts a new structure design. The control cabinet dimension is only 1/3 of other products on market. The multi-parallel architecture is the best way for cell culture process development, optimization, and characterization in a scaled-down model.

Copyright © Shanghai Duoning Biotechnology Co., Ltd. All Rights Reserved Sitemap | Technical Support:

Message-